Capabilities: Machining & Assembly

As an ISO 9001:2015 certified manufacturer, we consistently uphold strict standards through our Foundry process controls and quality systems. Our 215,000 square-foot Syracuse facility features 100 employees who work together to handle mid to high volume orders.

Our cross-trained staff offer complete custom manufacturing as well as manual and semi-automated assembly solutions for clients serving industries such as oil, gas, water rail, military, automotive, heavy truck and mining applications.

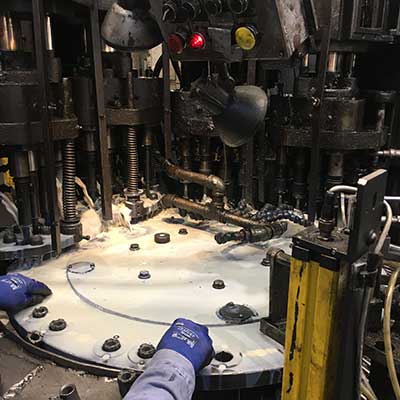

Machining & Assembly Equipment

- Eight Lead Screw Type, Multi-Spindle, Rotary Table, Auto Eject Drill & Tap Machines

- One CNC, Rotary Table, Multi-Spindle, Pick & Place Feed & Auto Eject Drill & Tap Work Cell

- Four Greenerd 20T Hydraulic Presses

- Five Dennison, Rotary Table 20T Hydraulic Presses

- Three Niagara, OBI, Mechanical Presses

- Two JetWheel MT-14B Shot Blast Machines w/ Hytrol Inspection Conveyors (HI Area)

- One JetWheel MT-22 Shot Blast Machine (Final Inspection Area)

- One Blastec 20 Cu.Ft. Shot Blast Machine (Final Inspection Area)

- One Pangborn 12GN1-644 Blast Machine (Final Inspection Area)

- Six Vulcan/Fox 320-42 Belt Grinders

Raw Castings to Finished Products

Frazer & jones is a world leader in the development, design, and manufacture of high-quality products from raw castings to finished products. We are committed to partnering with our customers and outside secondary sources to provide superior products to meet and exceed their requirements.

Frazer & Jones

3000 Milton Avenue

P.O. Box 605

Solvay, NY 13209

(315) 468-6251

salesandinfo@frazerandjones.com

Operations

Bill Rattray

General Manager

Bill Rattray

Finance

Diane Raber, Controller

diane.raber@sheetsrun.com

Accounting

Invoices@Frazerandjones.com

R & D/Technical

Michael Reilley, Technical Manager

MReilley@frazerandjones.com

Human Resources

Ihor Semko, MBA

Head of Human Resource

Isemko@frazerandjones.com

© Frazer & Jones • Site: D2P Web Design

Frazer & Jones • 3000 Milton Avenue • P.O. Box 605 • Syracuse, NY 13209 • 315-468-6251